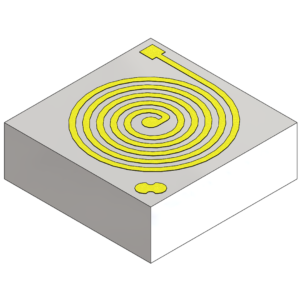

Spiral Inductors

Spirals

Wire Bondable Thin Film Spiral Chip Inductors

Inductance: 2.1 – 219 nH

Footprint: .020 x .020 up to .080 x .080

Alumina & Quartz Materials Available

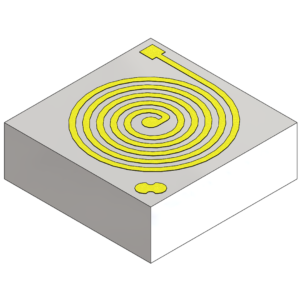

Wire Bondable Thin Film Spiral Chip Inductors

Inductance: 2.1 – 219 nH

Footprint: .020 x .020 up to .080 x .080

Alumina & Quartz Materials Available